In the global beauty industry today, there is one gigantic hurdle to overcome: everything feels and appears the same. Step into any store or browse through an online beauty boutique, and you’ll have dozens and dozens of products with basically the same promises. That is product homogeneity—where products have very little that differentiates them.

It’s a challenge that’s growing, especially for small and mid-size beauty businesses trying to sell in super-competitive overseas markets. With so many similar products, customers just buy the cheapest one. Price-cutting competition forces brands to give up profit margins, which slows down growth in turn.

So, how do you combat product homogenization and differentiation in a saturated market?

Let’s look at a real-life example of how one Middle Eastern skincare company went from selling close to zero to doubling and then tripling international sales through OEM customization.

The Problem: When Every Product Feels the Same

It is hard enough to start a skincare business. But when you try marketing the product in overseas markets like the Middle East, Southeast Asia, or Europe, it’s even harder. That is because these markets have already been flooded with the same type of product. Most firms use generic formulae, generic packaging, and copycat marketing.

This sets up a marketplace in which all is identical—and that is not good. For new or small brands, that sameness makes it nearly impossible to compete. They usually do not have the capital to invest in research and development, design, or global certifications. Even if they have the funding, their small production capacity limits how much they can actually grow.

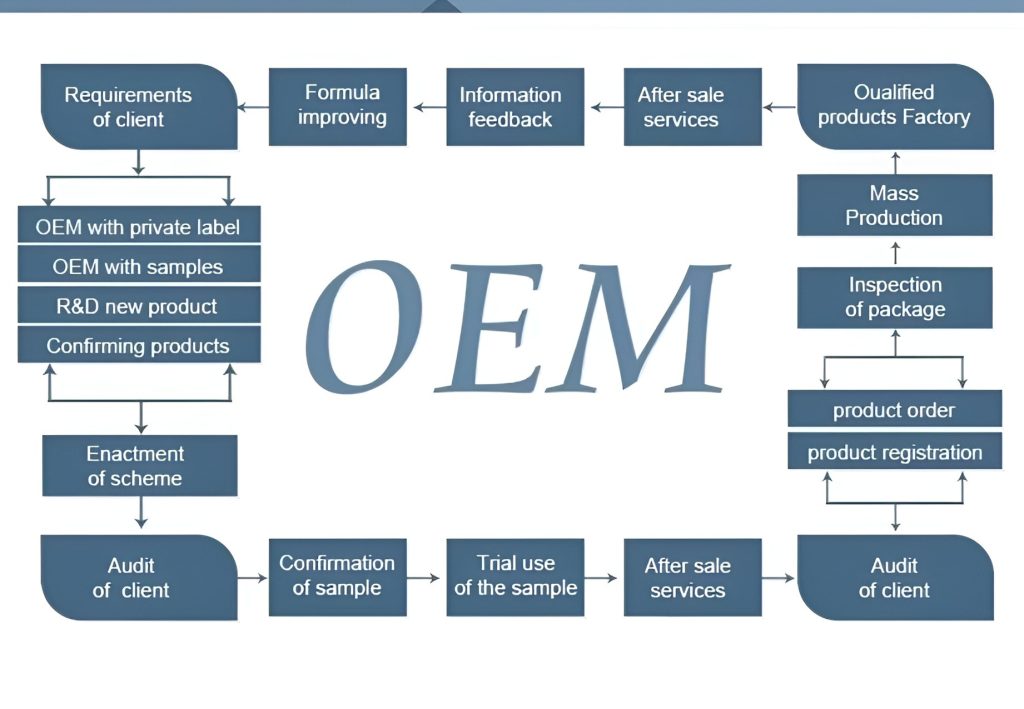

This is where OEM manufacturing services step in. With the skilled services of a skilled OEM cosmetic manufacturer, brands can produce bespoke products that are unique, functional, and ready for market

without having to construct a factory from the ground up.

But how does that, in fact, work in practice? Let’s consider an actual case.

The Turning Point: From “No One Cares” to “Overseas Hit”

1. Dilemma Prior to the Partnership

We begin with a small Middle Eastern skin care firm. They were skin care fans and had a decent following of their own. But when they tried selling online, it didn’t quite work out.

Their offerings did not fare well. Local dealers and distributors complained that the offerings seemed too generic—there was no distinction from the other offerings on the shelf. The company did not have in-house R&D, a small plant infrastructure, and was not equipped to deal with the complex certification process involved in export.

The outcome? Lackluster sales, soft customer demand, and no traction in the global beauty marketplace.

This is the common story of Middle East B2B beauty wholesalers and other small players in Southeast Asia and indeed in European markets. They simply don’t have the equipment or personnel to meet the requirements of overseas customers.

So what happened?

2. How OEM Customization Turned Things Around

The company teamed up with one of the leading OEM cosmetic makers, offering full-cycle OEM manufacturing solutions. However, this was not production outsourcing for the purpose of outsourcing production—it was a tight alliance founded on understanding the target market and developing the right product strategy.

Demand Diagnosis: The first job was to understand what Middle Eastern consumers truly required. The OEM team analyzed consumer trends in the Middle East and found opportunities in functional skincare in the form of sun protection, moisturizing, and anti-aging, and local packaging trends.

For example, whereas the brand had hitherto used plain plastic packaging, the new product had eco-friendly, gold-embossed glass packaging that was more appropriate for the Middle Eastern beauty consumers.

Full-Chain Empowerment:

- R&D Support: The cosmetics factory provided more than 30 sample choices in alignment with the brand vision. The team employed versatile small-batch production lines to quickly try out new formulas.

- Production Capacity: With 23 sophisticated production lines and a 150 tons daily production capacity, the factory never had any problem taking greater orders whenever demand was high.

- Compliance Help: The OEM also helped the brand pass strict international certifications like GMPC, ISO, and FDA, making it easy to enter regulated markets like the EU and USA.

Through the combination of strong product knowledge and private label cosmetics manufacturer support, the firm completely transformed its business operations.

3. The Results: Data That Tells the Story

The transformation was obvious and rapid.

In one year alone:

- International orders went up from 2 million to 7 million units

- The repurchase rate grew by 35%

- The brand was placed as an “Annual Innovation Single Product” on a top cross-border beauty platform.

- Middle East awareness grew by 60%, and the company became a regional brand of choice.

This growth would never have been possible without OEM customization. Not only did the company resolve its issue of sales, but it also became a market leader.

So why is this method so powerful? Let’s walk through.

Why OEM Customization Works: 3 Major Advantages

1. It Solves Product Homogenization with Real Customization

In contrast to traditional manufacturing, which produces hundreds of thousands of one particular thing, modern OEM manufacturing services are designed to be adaptable.

Small businesses are able to create unique, functional products—though in small quantities of orders—because of small batch production capacity. This is one means for firms to pilot formulas, designs, and packaging with minimal risk.

Want a light skin serum with anti-aging properties? Try three variants within a week. Want packaging that complies with European and American B2B cosmetics suppliers’ needs? No problem. Such flexibility allows it to be distinctive in a crowded marketplace.

2. The Factory Isn’t Just a Supplier—It’s a Partner

The finest cosmetics plants now not only produce products. They are service-oriented partners who help with:

- Formulation & testing

- Design and packaging

- Regulatory certification

- Logistics support

With its 50,000 square meter plant, 23 lines, and 150 tons per day output, this case study OEM partner was able to expand in tandem with the brand’s success. It also had the technical capabilities needed to assist in obtaining certification for countries like Indonesia (BPOM) and the European Union (CPNP).

This type of support allows brands to avoid the inconvenience of negotiating with five independent suppliers and focus on expanding their business instead.

3. Better Cost, Better Speed, Better Focus

It may take millions to set up your own factory. However, with cooperation with a credible private label cosmetics factory, brands can save as much as 70% of startup costs.

And it has nothing to do with the money. The lead time from design through delivery is reduced from the industry norm of 60–90 days to 45 days. That translates into quicker product launch, quicker customer response, and more opportunities to win in the marketplace.

With a reliable partner, you have nothing to worry about in terms of production, certification, or delayed delivery. You can focus on branding, marketing, and long-term customer relationships.

The Data Behind the Factory: Why It Works

Don’t just look at promises when choosing an OEM partner. Make them explain what they can really do.

1. Production Scale That Expands With You

A top-of-the-line OEM cosmetic manufacturer should offer:

- Multi-category flexibility (hair care, skincare, personal care)

- Parallel project support to prevent slowdowns

- Real-time data and supply chain visibility

Such assistance is specifically needed to help develop Southeast Asian B2B cosmetics producers and brands operating in dynamic European markets.

2. Quality That Builds Trust

The best cosmetic plants to invest in:

- 100,000-level cleanroom workshops to prevent contamination

- Global certifications like GMPC, ISO9001, and FDA

- Robotic equipment to reduce human errors

The reward? A 98% on-time shipping rate and extremely low product risk, even on expedited orders.

How to Select the Best OEM Partner: A Quick Guide

Not all producers are equal. Before you sign, ask these three questions:

- Can you provide the entire process, from design to certification?

Don’t handle multiple vendors.

- Do you prefer small batch production?

Test the market first before venturing into bulk supplies.

- Do you have success stories in similar markets or categories?

For example, if you want to reach the Middle East B2B cosmetic suppliers market, look for results within that particular region.

Red Flags to Watch Out For:

- Prices that seem too cheap

- No certifications

- No factory whatsoever—only a merchant house without any intention of production

Always choose OEM partners who have brick-and-mortar factories, well-established track records, and transparent communications.

Conclusion

Among a sea of lookalikes in beauty, authenticity is where genuine growth occurs. OEM customization is not a way to manufacture products—it’s a whole system to help brands stand out, grow, and succeed globally.

From groundbreaking new product formulas to rapid shipping and full certification support, the ultimate OEM cosmetic manufacturer puts small brands and large brands on an even playing field—with no hefty price tag.

Are you ready to make your own change? Reach out to us here to find out more about how our brand factory customization strength can assist. Farewell sameness—and hello success for your products.

BonnieCo, with over 15 years of experience in cosmetics manufacturing and private-label services, specializes in providing OEM/ODM one-stop solutions for your skin and hair care products.

Frequently Asked Questions (FAQs)

1. What is OEM customization for skincare?

OEM customization of skincare is working with a company to create proprietary formulas, packaging, and brand names unique to your market. At Bonnie & Co. Beauty, we offer turnkey OEM manufacturing to make your products distinctive.

2. How does OEM assist in addressing product homogenization?

OEM enables your brand to offer differentiated, region-specific skincare. We are experts in how to fix product homogenization through customized formulas, packaging, and certifications.

3. May I order small volumes to pilot test my market?

Yes, Bonnie & Co. is well-suited for small batch production, and it is great for testing your products in the local or overseas market before mass production.

4. What kind of certifications do you offer for global markets?

We assist with certifications like GMPC, ISO, FDA, BPOM (Indonesia), and CPNP (EU), so your products are ready for export.

5. Do you stock Middle East or Southeast Asian brands?

Indeed. We have successful partnerships with B2B cosmetics suppliers in the Middle East as well as Southeast Asian B2B cosmetics suppliers, with localised formulas and packages.

6. What distinguishes Bonnie & Co. from the other OEM cosmetics manufacturers?

We offer end-to-end service from R&D and packaging to production and compliance, making us not only an OEM cosmetic manufacturer but a long-term business partner in your success.

7. Do you help me create a private label skincare brand from the ground up?

Yes. With our credible private label cosmetics manufacturing reputation, we guide you through every step of formulation to design to delivery so that you can comfortably introduce your brand.

8. Design to delivery, how long does it take?

With our streamlined process and high-efficient cosmetics factory, we can have your final products to you within just 45 days—less than the industry average.

9. Do you use local or eco-friendly packaging?

Yes. We customize packaging to meet your brand’s values and regional trends, like environmentally friendly options for European and American B2B cosmetic suppliers.

10. How do I get started with your OEM manufacturing services?

It’s easy! Contact us here to schedule a free consultation and learn from the professionals how OEM customization can grow your skincare business.