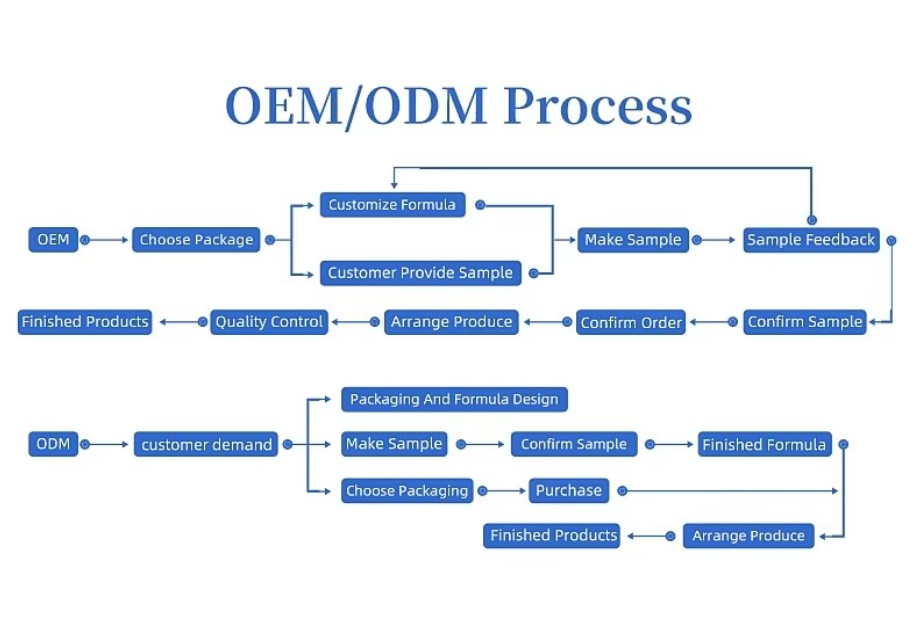

The beauty industry is expanding daily, and many brands are on the lookout for ways of developing new hair care products without developing their factories from scratch. That is where OEM or Original Equipment Manufacturers and ODM or Original Design Manufacturers come into play. It assists the brands in manufacturing affordable custom hair care products effectively by providing the various services involved in the process.

However, manufacturing hair care products is not as easy as people may think. To guarantee that a final end product is as per the set quality, it is always a difficult task that demands adequate planning, quality control, and technology. At BonnieCo, being an OEM/ODM professional cosmetics manufacturer, each and every process and operation is focused on providing customers with the safe, efficacious and high quality hair care product.

Well, how does a manufacturer turn an idea into something tangible and ready for use by the consumers? Now, let us start with the whole process from the beginning to the end.

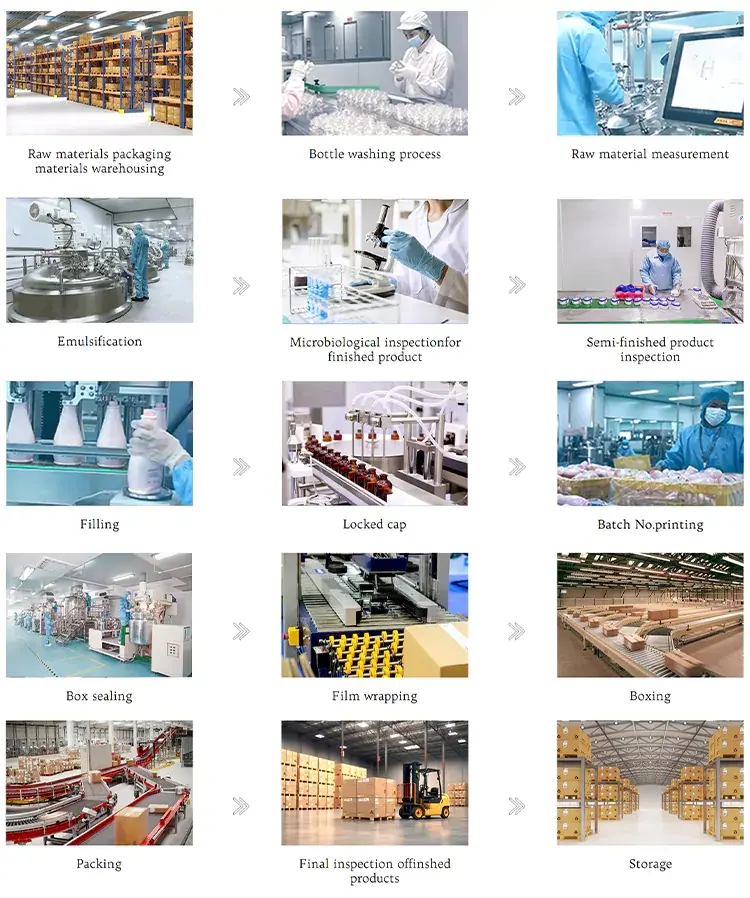

1. Raw Material Management and Production Preparation

The raw materials and packaging materials to be incorporated into the product must first undergo thorough handling and testing by the manufacturers. As observed, each compound that could be used in the actual creation and manufacturing of the product must also conform to safety measures and quality requirements.

Raw Material and Packaging Material Management

The first processes in custom hair care products would include purchasing the right ingredients and the correct packaging materials. This involves:

- Supplier Selection: In the case of a private label cosmetics manufacturer like BonnieCo., supplier selection is very crucial, as the company relies on the suppliers that offer good quality of raw material. This serves the purpose of ensuring that the ingredients being used are safe, reliable as well as standard.

- Warehousing Standards: All the related stocks and products must be stocked under the right conditions as outlined in the GMP. This tends to minimize contact between the products and the environment and hence ensures that the products are not contaminated hence enhancing the quality of the products.

- Raw Material Testing: Testing is done on raw materials before the production process. This involves checking whether the materials are safe for use. This process is called Raw Material Testing, and it comprises some basic physical-chemical tests as well as those that test for microbes.

Pre-Production Processing

After testing, materials are ready for use in the production process—the manufacturing Cycle and assembly line. This step means that all the ingredients are handled properly before they are processed within the main OEM/ODM hair care products line.

- Cleaning and Sanitizing Bottles: All the bottles follow medical grade washing to ensure it does not harbor any form of bacteria.

- Accurate Measurement of Raw Material: The company also uses electronic weighing to measure each and every raw material to maintain the required formula. This makes it possible to have standard production across all the batches of the products that the company produces.

The next step in the development of the hair care formula is under way as the materials have been procured.

2. Core Production Steps

Among those factors, the blending and stabilizing steps are considered to be the most critical stages of OEM/ODM hair care products. This step has the overall intention of ensuring that the formula that was developed is one that meets the required criteria and necessary standards such as efficacy, safety and texture.

Emulsification and Ingredient Fusion

Most custom hair care products require something commonly called emulsification where oil soluble and water soluble ingredients are combined. If developed without due consideration to emulsification, it might settle down at the bottom or deteriorate in effectiveness.

- Mixing: In a high shear process, called vacuum homogeneous emulsification technology is used for better blending of ingredients. This does not allow the product to segregate and hence enhances its quality.

- Temperature Control: Some of the raw materials have to be at certain temperatures in order for the correct characteristics to become achievable. Sophisticated temperature control systems maintain the active ingredients in the mixture and ensure that the proposed mixture is stable.

Quality Inspection and Semi-Finished Product Control

Before the formula can be packaged, it will undergo some tests in order to meet the standard expected of product. These tests assist in upholding the quality inspection standard as provided by the international policies and laws.

- Microbial Testing: This test helps to check the presence of bacteria, mould, and other forms of microorganisms that would be dangerous to use.

- Viscosity, pH, and Stability Testing: These tests confirm that the product has the right thickness, pH balance, and stability over time. If any issues are found, adjustments are made before moving on to the next step.

Only then can the product go to the Automated Filling Process and packaging of various products in the company.

3. Automated Packaging and Batch Management

The other steps involve the formula being put in a container in a manner that retains the quality and the appearance that is appealing to the buyers. In this aspect, it involves affixing a proper label and sealing each product appropriately.

Filling, Capping, and Batch Number Management

The automated filling process involves filling each bottle or any other container to a specific quantity of the product. That way, there will be no wastage, and every single product in the market will be standard.

- Filling: Filling machines fill bottles at high speed and efficiently, without or with product leakage.

- Smart Capping: Proper and efficient bottle capping is essential to avoid spillage or contamination of bottled water.

- Batch Number Printing: Each manufactured product has a batch number that can help monitor its production and quality. It also assists in meeting market requirements and guarantees security in cases of recall.

Finished Product Packaging and Warehousing Management

Packaging plays an important role in keeping the product safe and making it attractive to consumers. This also assists in the guard of the product during transport or storage to the intended destination.

- Sealing and Film Wrapping: Such a process makes use of fully automated machines to seal as well as wrap the products hence ensuring that they are not tampered with in any way. It also assists in reducing the cost of packaging of hair care products since there will be less packaging to do.

- Final Quality Inspection: The last check involves assessment of the packed product on various aspects such as the appearance, packaging, and its ability to maintain its quality for some time after packaging.

- Efficient Warehousing System: This implies that it should be stored in a proper manner and the best place for storage to ensure large orders are shipped without delays.

4. Why a Professional Manufacturer Matters

The entire OEM/ODM hair care products process is elaborate and a lot of precision is needed when developing the product line. BonnieCo gives importance to its production processes such as Raw Material Testing, the emulsification technology they utilize and the Automated Filling Process.

Choosing an experienced private label cosmetics manufacturer means that brands can offer high-quality custom hair care products without worrying about production issues. Working with a trusted cosmetics factory also provides access to advanced production process methods, ensuring that products meet international standards.

Conclusion

Hair care product manufacturing is not just a process of combining various raw materials. In the OEM/ODM hair care production, every process, including materials purchasing, source, emulsification technique, etc., is important for a successful product.

BonnieCo offers complete OEM and ODM services to assist brands in creating custom hair care products ideal for the market. The cosmetics factory maintains high standards of quality control to avoid compromising quality, safety, and time.

We are the right cosmetics manufacturer for you if you need help producing your hair care products. Contact us today to start your journey toward creating high-quality, customized hair care solutions.

Frequently Asked Questions (FAQs)

1. What is the OEM/ODM hair care product process?

It is the production of hair care products specifically for labels and trademarks under the client’s formulation (Original Equipment Manufacturing/ OEM) or provided fully formulated products for the client to label (Original Design Manufacturing/OEM).

2. How does BonnieCo ensure product quality?

We follow strict Raw Material Testing, microbial testing and stability checks are conducted in adherence to the highest standards.

3. Can I create my own hair care formula?

Yes, Hair Care Formulation Development is one of the services offered by our company to develop new products for your range.

4. What types of hair care products can be made?

We offer products like shampoos and conditioners, hair masks and serums, and hair styling products such as hair treatments.

5. How long does production take?

The production period is estimated to take between 3 to 6 months for the formulation, testing, and packaging.

6. What packaging options are available?

We offer various hair care product packaging options, including bottles, jars, and tubes.

7. What is emulsification technology?

It’s a process that blends water and oil-based ingredients to create smooth and stable formulas.

8. How does automated filling help?

The Automated Filling Process ensures precision, reduces waste, and improves production speed.

9. Can I request small batch production?

Yes, but minimum order quantities (MOQs) apply based on product type.

10. How can I start working with BonnieCo?

Contact us to discuss your needs and begin the OEM/ODM hair care product process.